Find the pages, products, documents, and resources with a full site search.

Advanced Document SearchSponge-Jet enables heavy equipment rebuilders to clean parts faster and with better quality, resulting in reduced disassembly time and like-new paint finishes on refurbished components. The improved surface preparation and resulting coating benefits reinforces the overall quality associated with a certified rebuild.

Sponge-Jet Custom Integrations eliminate many of the problems caused by ordinary cleaning systems and abrasive grit blast rooms. All solutions provide simplicity, consistency and efficiency. This waterless, environmentally friendly process requires less capital investment, less system maintenance, and less ongoing operational costs than competitive industrial solutions.

Features & Benefits

- Effectively remove grease, oil and dirt

- Clean exterior parts the first time

- Environmentally friendly

- Cuts down on the secondary hand-cleaning of components

- Efficient enough to produce a clean surface to repaint

- Enhances the look of the final product

- Work adjacent to mechanical assemblies, rotating equipment and electronic devices

- Spend less on media handling and conveying

- No reclamation augers, mechanical buckets, or conveyors

- Simple, low maintenance vacuum recovery solutions

- Reduce H/VAC costs by HEPA filtered recirculating air

- New blast rooms can be built for a fraction of the cost of conventional blast rooms

- Existing blast rooms can be easily converted

- Allows for precision cleaning, touch-up and controlled feathering of existing coating

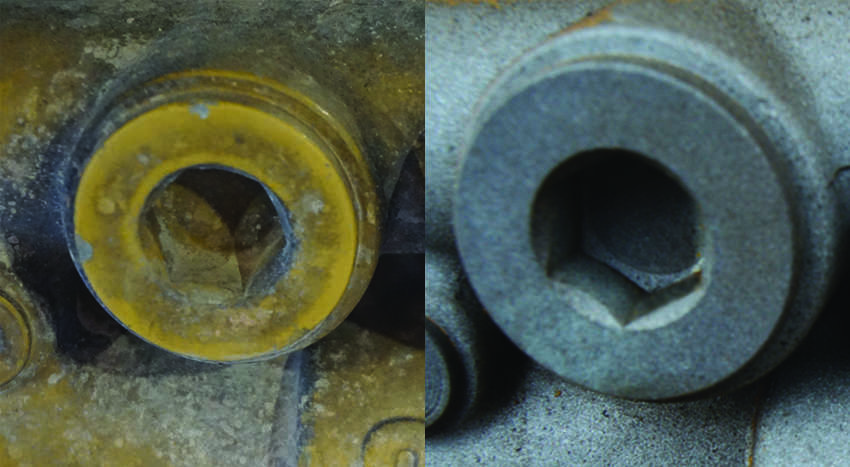

Cleaner Bolt Heads

This heavy equipment rebuild center uses Sponge Media™ to reduce disassembly time by completely clearing bolt heads of paint, grease, and grime. This allows wrenches to fit fully into the bolt head; proper tool engagement reduces rounding of bolt head, snapping bolts off and stripping threads.

Remove Grease and Oils

Blasting with Sponge Media™ gives manufacturers an advantage over cleaning oily and thick, greasy surfaces. As other abrasive technologies spread oil and/or grease contaminants around the surface. Sponge Media removes them, leaving a clean (paint-ready) substrate.

Media Choice

Silver 80 Sponge Media™ was selected by a large construction equipment dealer in Mexico to prepare new and refurbished parts for coatings; selection was based on the ability to provide one-step cleaning and removal of weld oxidation and silicates; achieved profile ±50μ (±2mil).

Reduce Grit Intrusion

An aerial lift manufacturer switched to a Sponge-Jet Integrated System for surface preparation in their equipment reconditioning division. Steel grit was migrating into motors and causing premature failure. The switch to Silver 30 Sponge Media™ (±75μ (±3mils) saved significant time by not requiring disassembly of each lift.

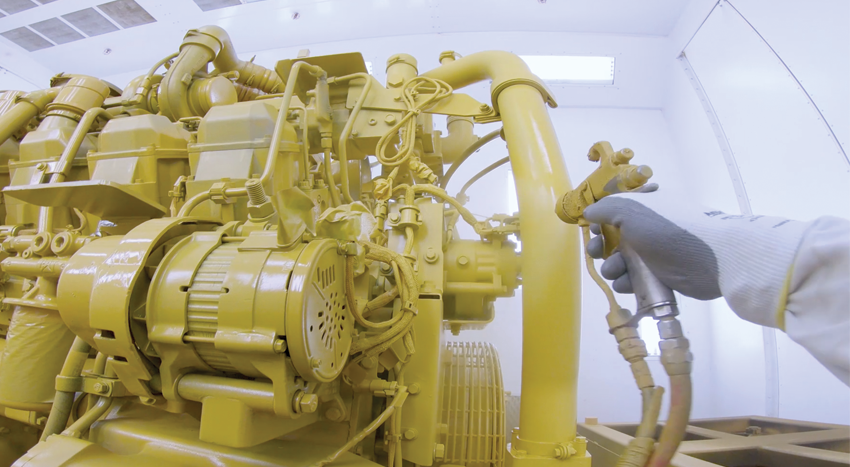

Better Surface to Paint

Final coatings look as good as new without paint layers showing; this helps reinforce the high quality of the rebuild as perceived by the customer.

Tough On Coatings, Not Equipment

No other single process is as effective at cleaning and removing paint without damaging equipment

Sponge-Jet Resource Center

Resources

Sponge-Jet Resource Center

Resources

Typical Sponge-Jet Cleaning Room Layout

…

Download

Sponge-Jet Engine and Component Cleaning and De-painting

…

Download

Sponge-Jet Introductory Brochure

PDF document shows how Sponge-Jet’s abrasive blasting technology protects worker health and the en…

Download

Component Rebuild Center (CRC) Overview

…

View Video

Blog

Recent Blog Posts

Robotica Saves Disposal and Labor Costs in Mexico

Pipelines are crucial for transporting clean water from treatment plants to cities, businesses, and homes. By maintaining a closed piping system from the source to the faucet, water utilities reduce the risk of water contamination. During the manufacturing of these pipes, proper surface prep must be completed to ensure that they maintain their integrity after coating and installation.

Read More >

How Sponge-Jet Helped Restore Paris's Grand Palais for the 2024 Olympics

Every four years, billions of people from all around the globe unite to watch the Olympic Games.Hosted in renowned cities worldwide, this year’s Olympic Games will be held in Paris, France. They have only been held in Paris, France twice before - in 1900 and 1924. Now, 100 years later, Paris will once again become the world stage for these iconic games.Read More >