Find the pages, products, documents, and resources with a full site search.

Advanced Document SearchSurface Preparation Solutions for Salt Water Environments

Superior chloride removal, extended coating life and ability to work near sensitive equipment are just a few of the features that make Sponge-Jet technology indispensable to the US NAVY and many of the largest ship owners and builders worldwide.

- Erection welds and fit-out welds during new construction

- Bilges, ballast tanks and engineering spaces

- Mechanical rooms, accommodations and topside

- Tanks (lube oil, sumps, grey-water and potable-water)

- Submarines, yachts, Naval vessels, cruise ships and super-yachts

- Offshore platforms, drill ships and FPSOs

- Ship-builders, shipyards, dry docks, ship owners and marine contractors

Sponge Blasting with composite abrasive removes chlorides and tough marine coatings, leaving the surface cleaner, more consistent (higher quality) than other surface preparation methods.

Features & Benefits

- Cost savings

- Protect integrity and reliability of equipment

- Improve worker health and safety

- Blast on operating equipment

- Improve community relations and compliance

- Increase asset life and coating performance

Protecting Erection and Fit-out Welds on Ice Breaker

This unique ice breaking tanker and winner of “Ship of the Year” used Sponge-Jet Silver 30 Sponge Media™ to prepare erection and fit out welds. The owner demanded 100% sponge blasting of the welds. Ship inspection five-years later proved positive (unlike other ships) with virtually no corrosion anywhere on the ship.

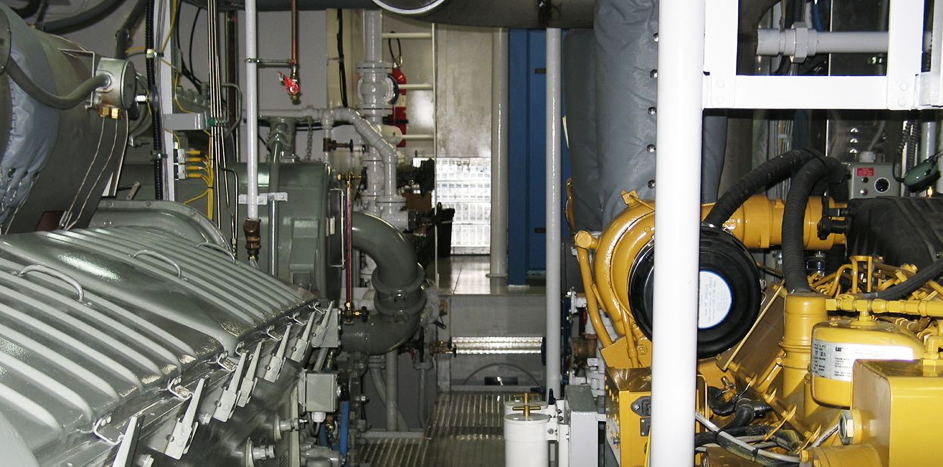

Extending Coating Life in Machinery Spaces

Prior to the use of Sponge Media™ abrasive blasting, these difficult areas were maintained with power tools and constantly being repainted. The short life of power tool prepared coatings drove significant costs and a need for constant maintenance. Sponge-Jet now allows proper preparation and long-term coating life in these challenging machinery spaces.

Ease of Sponge Blasting in Tanks and Confined Spaces

Confined spaces, especially on board ships, offer unique challenges for proper ventilation and access during blasting operations. While some ventilation is still required during Sponge Blasting in these areas, the 98% reduction of dust allows for simple, safer staging of these projects.

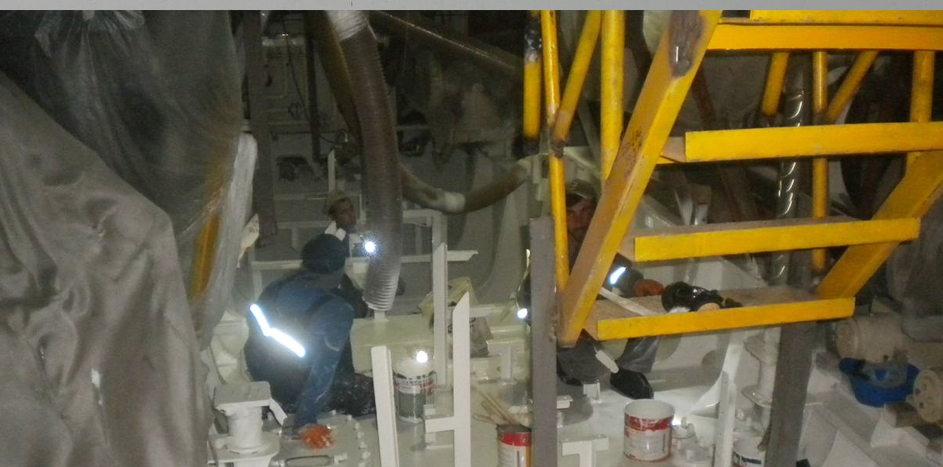

Superior Preparation while Allowing Others to Work Concurrently

Few areas challenge coatings more than here – a combination of high-speed turbulence near the propeller, dis-similar alloys, weld seams & cathodic protection all create challenges to a coating system. Sponge-Jet not only provides a superior surface for coating but allows others to work on the propulsion system at the same time.

Superior Preparation After Block Construction

Examples of areas often left with less than an ideal coating system. Composite abrasive blasting with Sponge-Jet allows superior preparation after block construction or as part of a ship maintenance, without ricochet damage to adjacent surfaces. Additionally, dust during blasting can be controlled with simple portable negative air ventilators rather than large extraction ducts running outside the ship.

Multiple Blasters with Inspectors ; Even Painters Work Simultaneously

Proper ventilation of large confined spaces with limited access from 15m (50ft) above used to make cargo holds a challenge. Now multiple blasters along with inspectors and even painters can all operate simultaneously with less staging and ventilation challenges than in the past.

Sponge-Jet MicroContainment™ Limits Dust – Makes Hull Repair Fast and Easy

When the fairing compound separates from its steel hull, the super yacht owner understandably has no interest in having the hull sandblasted - putting dust throughout this prized possession. Sponge-Jet’s MicroContainment™ technology limits the dust so that conventional marine shrink-wrap separating the hull from the deck can be used as containment – and repairs can be made quickly and reliably.

Abrasive Blast in Construction Halls While Trades Continue Fitting Out Ship

Normally it is difficult to abrasive blast inside construction halls while other trades are still fitting out a ship. However, with composite Sponge Media™ abrasives this is a standard procedure – from Australia to USA to Germany. Small barges, aluminum ferries or the largest cruise ships, the choice for blasting in construction halls without interruption of construction – is Sponge Blasting.

Sponge-Jet Reduces Labor; Allows Simultaneous Blasting, Clean-up and Inspection

Many shipyard blasting projects are staged such that one shift blasts, another crew cleans up followed by inspection. By Sponge Blasting all work can operate concurrently, reducing the time-line, supervision requirements and overall costs. With Sponge-Jet a hardworking three-man crew can support two blasters and one other cleaning and recycling simultaneously.

Top-side Blasting of Pipes and Accommodations; Possible with Low-footprint Abrasive Blasting

In dock, during construction or underway, Sponge-Jet technology is used on-board for surface preparation prior to coating ship decks, stairs, accommodations and process piping. Sponge Media™ abrasives are recyclable and therefore require less material to dispose, transport and haul to/from the site. The process also greatly suppresses dust which protects sensitive equipment and nearby local environment.

Stop Your Marine Coating Projects From Becoming One of the 75% of Coating Failures

Yachts, ferries, cruise ships, military vessels, FPSOs and commercial ships of every type need longevity from their coating systems. Over 75% of coating performance can be attributed to surface preparation. Sponge-Jets has a track record of adoption and use in every marine segment, year after year.

Sponge-Jet Resource Center

Resources

Sponge-Jet Resource Center

Resources

819 Restoration on Harpers Ferry Class Dock Landing Ship

Case history about Sponge-Jet replacing hand tools on sidewall and catwalk restoration of USS Carter…

Download

Low Dust Ballast Tank Blasting with Sponge-Jet

This blaster is conducting confined space, low dust abrasive blasting in a ship’s ballast tank…

View Video

Marine Overview Video

Sponge-Jet’s low dust abrasive blasting technology is widely used in the marine industry by mi…

View Video

Prep for Life Marine Maintenance Tech

PDF magazine article describes modern marine coating’s higher anchor profile requirements and the …

Download

Blog

Recent Blog Posts

Robotica Saves Disposal and Labor Costs in Mexico

Pipelines are crucial for transporting clean water from treatment plants to cities, businesses, and homes. By maintaining a closed piping system from the source to the faucet, water utilities reduce the risk of water contamination. During the manufacturing of these pipes, proper surface prep must be completed to ensure that they maintain their integrity after coating and installation.

Read More >

How Sponge-Jet Helped Restore Paris's Grand Palais for the 2024 Olympics

Every four years, billions of people from all around the globe unite to watch the Olympic Games.Hosted in renowned cities worldwide, this year’s Olympic Games will be held in Paris, France. They have only been held in Paris, France twice before - in 1900 and 1924. Now, 100 years later, Paris will once again become the world stage for these iconic games.Read More >