Find the pages, products, documents, and resources with a full site search.

Advanced Document SearchPrecision Cleaning & Rehabilitation

Architects, conservators and engineers need to specify products and methods of surface preparation and cleaning that will maintain the integrity of the surface.

Chemicals may be difficult to dispose, water may be difficult to contain, and ordinary abrasive materials may damage the substrate.

Sponge-Jet’s proven technology is chosen by professionals to precisely clean and remove surface contaminants from sensitive substrates:

- Tin, bronze, brass, copper, gold and all other metals

- Clean stone, marble & masonry substrates

- Environmental contaminant removal

- Lead abatement

- Graffiti removal

- Stone

- Wood

Inspectors can observe the surface cleaning in real time for better control of their project—all while protecting the environment.

Features & Benefits

- Simplified job staging

- Reduced compliance requirements

- Precision cleaning

- Improve community relations and compliance

- Support public environmental initiatives

Sponge-Jet Helps Restore Historic Courthouse while Protecting Workers and Public

Sponge-Jet protects the public during a courthouse coating restoration project; It was selected to suppress lead-based dust during complete coating removal from cast iron cornices on the Historic Marion County Courthouse.

Mass State House Turns to Sponge-Jet to Safely Remove Lead-Paint

Sponge-Jet partners in the safe restoration of the Massachusetts State House; Sponge Media™ abrasives were used to remove multiple layers of lead-based coatings from structural steel beams (adjacent to sensitive glazed white brick ceiling tiles). Removal relied heavily upon the reduced rebound (protecting tiles) and the process’ ability to contain hazardous coating particles at the source of generation.

Removing Accumulated Environmental Pollutants from Historic NYC Museum

This historic facade contained multiple stone types, all heavily soiled from years of city smog and acid rain. Here the preservationist easily adjusted for each stone type and was able to clean adjacent to place windows.

Sponge-Jet on Early Synagogue; Helps Win Esteemed Carolopolis Award

Sponge-Jet helped de-paint and clean the exterior of the second oldest Synagogue in the US; the preservation project used Sponge Media™ micro-abrasives to remove layers of failed coating from the building’s various substrates – in doing so the preservation project won the esteemed Carolopolis Award.

Restoring Copper Roofs While Preserving Patina

This highly skilled team, specializing in remote access technology (repelling from ropes) used White SPOCC Sponge media™ at low pressure to clean environmental staining from the copper roof of the Oakland Tribune Building. Containment debris nets were positioned below as they freely blasted high above the city.

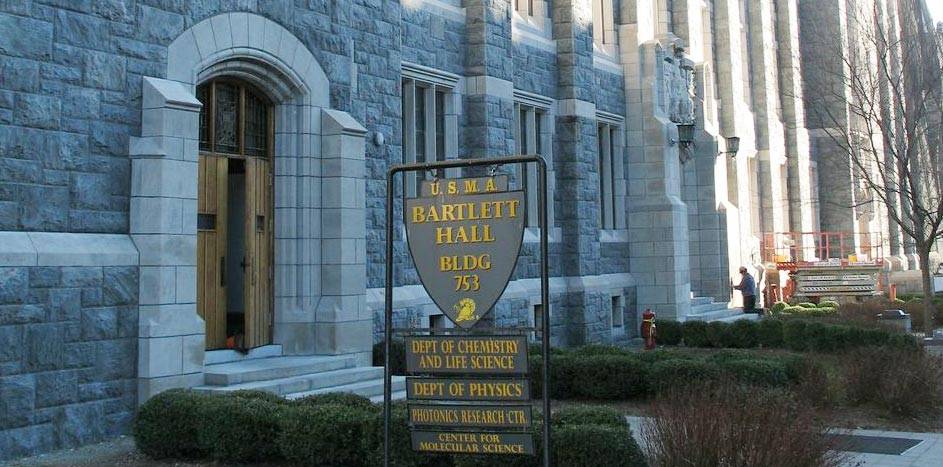

Removing Efflorescence from Olean Granite Blocks at West Point

West Point’s Bartlett Hall was the perfect to setting to show Sponge-Jet’s ability to remove efflorescence from the hall’s exterior Olean Granite blocks; even better were the constraints… no moisture… no fugitive emissions and no interruption to ongoing classes and activities scheduled in the building.

Removing Lead-based Paint from Decorative finals atop a NYC Landmark Skyscraper

The Guilder’s Studio, charged with restoring roof-top decorative copper lanterns on the New York Life Building, chose Sponge-Jet to controllably remove multiple layers of lead paint, provide proper cleanliness and the specified anchor pattern for the sizing primer – ultimately preparing the finals for gold gilding.

Mexican Urban Sculptures Get Facelift with Sponge-Jet Without Damaging Complexion

The five Torres de Satélite structures were blasted with White Glass Sponge Media™ micro-abrasives to remove badly faded and peeling paint from their concrete substrates, but without damaging the substrate or causing interruption to the thousands of commuters passing the site each day.

Removing Soot and Environmental contaminants from Granite Architectural Headers

Cleaning a Grand Rapids Historic brick building and removing soot and environmental damage from granite architectural headers; see the remarkable before and after results.

Smoke Damage and Soot Removal From Cold-storage Building

Sponge-Jet cleans aged soot/burned coal residue from brick, wood surfaces, ceilings and trusses of historic, 1920 cold-storage building.

Restoring the William Tecumseh Sherman Statues; New York Icon and Landmark

The first major restoration of the William Tecumseh Sherman statue includes Sponge-Jet as the primary restoration technology; the bronze statue employed Sponge-Jet to remove the failing layers of guilding and then slightly profile it in preparation for resurfacing.

Lead Paint Removal From Iconic Fenway Park Brick Walls

Restoration contractor uses Sponge-Jet micro-abrasive control to regulate enough pressure with the right Sponge Media™ product to remove the accumulated layers of paint but without appreciable damage to the original brick facade

Cleaning Masonry Substrates and Architectural Sections in Sacred Heart Church

There was a Sponge Media™ product for every substrate in this historic church where every media equally dissipates collision energy so as not to cause additional damage to surrounding stained glass, icons and wood work.

Sponge-Jet Resource Center

Resources

Sponge-Jet Resource Center

Resources

A Capitol Project: The Restoration of the US Capitol

The massive, ornate Capitol dome may look like it’s made of plaster, but it’s actually layered c…

View Video

US Marine Corps Memorial Restoration

In the late 1940s private funds helped launch the development and construction of the United Stat…

View Video

Longfellow Bridge Restoration

The historic restoration of Boston’s Longfellow Bridge is now complete! The large scale granit…

View Video

Sponge-Jet Restoration

A major challenge conservators face is the uniqueness of each restoration project.

View Video

Blog

Recent Blog Posts

How Sponge-Jet Helped Restore Paris's Grand Palais for the 2024 Olympics

Every four years, billions of people from all around the globe unite to watch the Olympic Games.Hosted in renowned cities worldwide, this year’s Olympic Games will be held in Paris, France. They have only been held in Paris, France twice before - in 1900 and 1924. Now, 100 years later, Paris will once again become the world stage for these iconic games.Read More >

How do Contractors Use Sponge-Jet for Abatement Work?

Jobs that are characterized as "abatement projects" typically involve the removal of hazardous materials from the surface. These types of projects are often found in places like industrial shipyards, factories, tanks, water treatment plants, mill buildings, and generally any building or structure built before 1980.

Read More >