Earn Higher Margins By Providing Better Value and Total Cost Solutions To Your Clients

Avoid disruptions to client operations, drastically reduce risk of damage to their valuable equipment, provide them superior coating life and extend time between maintenance projects. Sponge Blasting technology allows contractors to provide more total value to their clients; it allows contractors to differentiate themselves and become an invaluable part of their customer’s team.

Testimonials

"Navantia... will continue counting on the Sponge-Jet technology for surface preparation and we congratulate you for the quality of your products and the service you provide us." - Pedro Pedraza Bergillos, Program Manager, Navantia

"The other cleaning methods are too destructive." Our goal is to leave the granite and tack and to remove only the dirt." - James S. Schumacher, Project Manager, J.P. Cullen & Sons Inc.

"SpongeJet is a much cleaner process for the interior repair and prep of our rail cars. The greatly reduced dust levels and easy cleanup has been a great benefit. The cost is slightly higher than conventional media but the ability to recycle and other benefits far out weigh the initial cost." - Billy Jones, Procurement & Operations, Trinity Rail

"With sponge-encapsulated media you could accurately control how much coatings you remove from section to section.” - Ron Rozek, President, Performance Solutions Advantage

"Visibility while blasting in an enclosed 12 foot diameter pipe was very good. Dust creation while blasting was so low that we simply hung a rain coat over the manhole." - Neil Murdock, President, Faith Water Works

"Nothing works as well as the sponges… "I've used just about every product there is. This is the right way to go. The results are unbelievable." - Chris Rizzi, J.S.L. Pressure Washing

"...we have been using [Sponge-Jet] for many years with nothing but excellent results, due to the fact the customer, Pemex Exploration and Production (PEP), continues regular operations while we use it." - Francisco Sánchez Pineda, Superintendent of Maintenance Operations, DIAVAZ

When you find yourself in a situation where you need to do blasting but need to control the dust and are concerned about safely and the environment, it's useful to know there's machinery that can do the job." - Shane Crowe, Branch Manager, Brisk Waterproofing Co. (Member of Western Construction Group)

Related Resources

Chloride Removal Paper

PDF white paper compares dry abrasive blasting with pliant abrasive blasting, focusing on chloride r…

Download

Chloride Removal Test

PDF letter describes how Sponge-Jet abrasive blasting lowered chloride levels below 10 mg/cm² in on…

Download

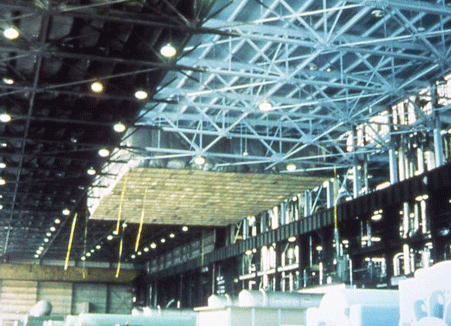

Paint Removal in Manufacturing Plant

PDF describes case history of Sponge-Jet low dust coatings removal inside robotics plant containing …

Download

Sponge-Based Technology Can Cut Cleaning Downtime

PDF article describes abrasive-blast airborne dust problem encountered at manufacturing facilities.

Download

Recent Blog Posts

How Sponge-Jet Helped Restore Paris's Grand Palais for the 2024 Olympics

Every four years, billions of people from all around the globe unite to watch the Olympic Games.Hosted in renowned cities worldwide, this year’s Olympic Games will be held in Paris, France. They have only been held in Paris, France twice before - in 1900 and 1924. Now, 100 years later, Paris will once again become the world stage for these iconic games.Read More >

How do Contractors Use Sponge-Jet for Abatement Work?

Jobs that are characterized as "abatement projects" typically involve the removal of hazardous materials from the surface. These types of projects are often found in places like industrial shipyards, factories, tanks, water treatment plants, mill buildings, and generally any building or structure built before 1980.

Read More >