Protecting Workers From The Hazards of Abrasive Blasting Materials

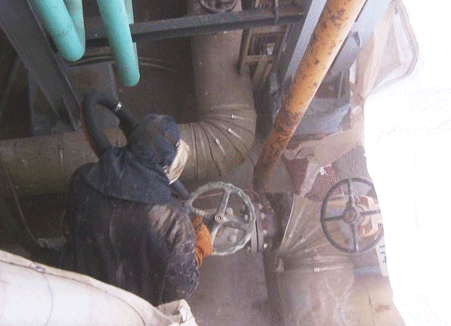

Worker health and plant safety issues are dramatically improved when Sponge-Jet technology is used for surface preparation. Fugitive emissions (TSP and PM-10) can be reduced as much as 97% over traditional abrasive blasting, drastically reducing reportable environmental emissions. Sponge Media particles capture the contaminants removed from the surface – reducing worker exposure to hazardous airborne dust normally caused during abrasive blasting. Injuries caused by abrasive ricochet are eliminated. Sponge Media is also recycled which can reduce waste disposal up to 96%.

The industry term “low dust blasting” is commonly being replaced by “dustless blasting.” Review the US Environmental Protection Agency for complete test results on abrasive emission factors in file AP-42 and its independent companion update “Emission Factor Documentation for AP-42 Section 13.2.6”

Testimonials

"We recommend Sponge-Jet as an environmental friendly abrasive blasting method which fulfills our health and environmental regulatory requirement.” - Mechanical Manager, TownGas

Related Resources

MRI – Emission Study

PDF document details laboratory test results that blast operations utilizing Sponge-Jet sponge-encap…

Download

Sponge-Jet Introductory Brochure

PDF document shows how Sponge-Jet’s abrasive blasting technology protects worker health and the en…

Download

California Air Resources Board Certification-CARB

PDF approval letter by California Air Resources Board (CARB) announcing certification that Sponge-Je…

Download

Lead Suppression Tests

PDF 3rd party report discusses results of Maine Department of Transportation airborne lead testing a…

Download

Recent Blog Posts

How Sponge-Jet Helped Restore Paris's Grand Palais for the 2024 Olympics

Every four years, billions of people from all around the globe unite to watch the Olympic Games.Hosted in renowned cities worldwide, this year’s Olympic Games will be held in Paris, France. They have only been held in Paris, France twice before - in 1900 and 1924. Now, 100 years later, Paris will once again become the world stage for these iconic games.Read More >

How do Contractors Use Sponge-Jet for Abatement Work?

Jobs that are characterized as "abatement projects" typically involve the removal of hazardous materials from the surface. These types of projects are often found in places like industrial shipyards, factories, tanks, water treatment plants, mill buildings, and generally any building or structure built before 1980.

Read More >