Find the pages, products, documents, and resources with a full site search.

Advanced Document SearchWhy Sponge-Jet

-

Suppresses up to 99% of dust.

-

Accelerates blasting & painting

operations

-

Reduces Downtime - saving millions

-

Lowers environmental impact

-

Proven

better in workplace

health & safety

- Suppresses up to 99% of dust.

- Accelerates blasting & painting operations

- Reduces Downtime

- Lower environmental impact

- Proven better in workplace health & safety

Industries

Benefits

- Extends Coating Life

- Increases Profits & Production

- Used by Fortune 100 Manufacturers

- Specified in Over 100 Refineries Worldwide

- OSHA-Recognized for Low Toxicity

- Safer for Operators

- Up to 20x Faster Than Power Tools

- Enhanced Visibility

- Versatile—Works on All Substrates

- Eliminates Harmful Rebound

- Specified by Governments Around the World

- Creates Any Required or Desired Profile

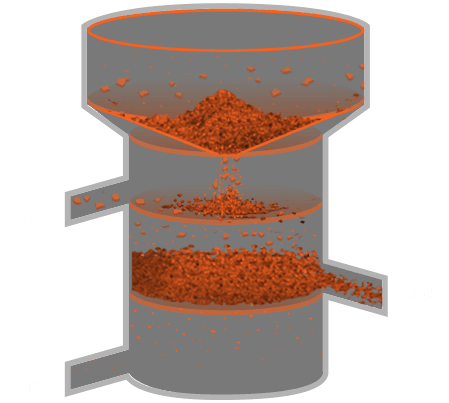

- Reusable Material—90% Lower Disposal Cost

- Replaces Multiple Blasting Systems

- Environmentally Engineered for Less Fugitive Emissions