Preserve History – Protect What’s Important

Sponge-Jet provides professionals with a dry, low-dust, micro-abrasive composite to clean multiple substrates across many applications.

- Removal of environmental contaminants

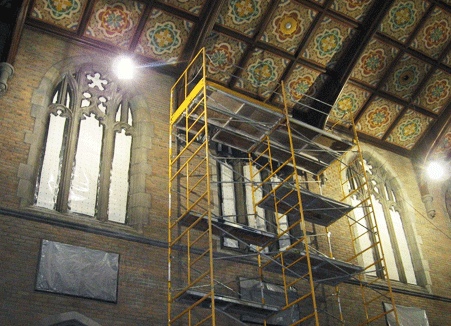

- Historic structures & monument rehabilitation

- Graffiti removal

- Lead paint remediation

- Efflorescence & exfoliation

- Soot, char & smoke damage

- Stone & marble cleaning

Materials can be selected that can remove contaminants without damaging the surface. This controllable system allows the operator to adjust pressures and media rates to match the needs of the project. The low rebound nature of Sponge Media prevents damage to adjacent surfaces, while the low dust feature enables the operator to visually watch and control contaminant removal during the process.

Testimonials

“In terms of preservation, graffiti is among the bigger problems we face on the wall because it’s fragile sandstone. In the past, we’ve had to use chemicals… Now, we have available gentle abrasive measures.” - Christina Wallace, Senior Preservation Conservator, Presidio Trust

“It had the advantage of keeping all of that lead contained. And they had worked out a process for cleaning the lead out of the sponge and then reusing the sponge. So we could get up there and remove the lead completely, and very easily." - David Kemnitzer, Preservation Director, Powe Jones Architects

Related Resources

Battery Chamberlin Preservation

Article on historic US Army gun at Battery Chamberlin (California) and how Sponge-Jet was selected b…

Download

Cleaning Wisconsin State Capitol

PDF magazine article describes how Sponge-Jet blast media was used to clean, exfoliate, and preserve…

Download

Courthouse Restoration Article Traditional Building

PDF magazine article describes using Sponge-Jet blast media to remove multiple layers of decades-old…

Download

Overview of Historic Restoration

DF document showcases Sponge-Jet’s ability to precisely clean sensitive and ultrasensitive surface…

Download

Recent Blog Posts

How Sponge-Jet Helped Restore Paris's Grand Palais for the 2024 Olympics

Every four years, billions of people from all around the globe unite to watch the Olympic Games.Hosted in renowned cities worldwide, this year’s Olympic Games will be held in Paris, France. They have only been held in Paris, France twice before - in 1900 and 1924. Now, 100 years later, Paris will once again become the world stage for these iconic games.Read More >

How do Contractors Use Sponge-Jet for Abatement Work?

Jobs that are characterized as "abatement projects" typically involve the removal of hazardous materials from the surface. These types of projects are often found in places like industrial shipyards, factories, tanks, water treatment plants, mill buildings, and generally any building or structure built before 1980.

Read More >