Find the pages, products, documents, and resources with a full site search.

Advanced Document SearchIncreased Equipment Reliability

For decades, the predictable event after an unplanned plant shutdown was a long chain of rotary and instrumentation failures. Running from floor-to-floor bypassing pumps and valves a week after abrasive blasting had taken place was a common situation for maintenance crews in every industry all over the world.

Today the clean, dry, low-dust, ricochet-free technology offered by Sponge-Jet Sponge Media™ increases reliability of all plant equipment by eliminating the pulverized particles of dust common to all ordinary dry abrasive methods.

With Sponge-Jet, expect protection to:

- Rotating equipment, shafts and bearings

- Hydraulic and pneumatic cylinders

- Electronics, switches, sensors and vision systems

- Mechanical seals

- Motors, engines, turbines and compressors

- Heat transfer surfaces

- Rails, guides, conveyors and transport systems

These fine, breathable, microscopic particles are not only toxic to humans but are a destructive enemy to all rotary, electronics and sensitive equipment.

Features & Benefits

- Cost savings

- Blasting on operating equipment

- Extended time between repairs

- Reliable schedule and budget

- Protected integrity and reliability of assets

- Increased asset life and coating performance

Machines Spaces while Underway

Prior to the use of Sponge Media™ abrasive blasting, these difficult areas were maintained with power tools and constantly being repainted. The short life of power tool prepared coatings drove significant costs and a need for constant maintenance. Sponge-Jet now allows proper preparation and long-term coating life in these challenging machinery spaces.

Blasting on Live Process Equipment

Pumps, valves and other process pipe components are all being prepared, while operating, at this Repsol fuel distribution plant. Normally the fugitive emission and dust would penetrate mechanical seals, bearings and other rotating items – causing future reliability issues. Now with Sponge-Jet, the plant maintains quality coating systems without compromise or fear of damaging sensitive equipment.

Refrigeration Pipes at Gas Plant

These refrigeration pipes were blasted live, during operations at this liquid gas plant - saving time and protecting nearby equipment. By completing the coating work during normal operations, future shut downs became shorten and less complicated as fewer trades were required to work all at once.

Offshore Flare Lines Blasted in Operation

Suspended over the ocean on an operating offshore platform this specialist is preparing the flare pipes for recoating by blasting with Sponge-Jet Silver 30 Sponge Media™ abrasives.

Blasting Flanges on Live Refinery Pipes

Shown here is an operator preparing pipework including bolted flanges during production. Note, proper grounding to avoid static sparks is imperative in flammable environments.

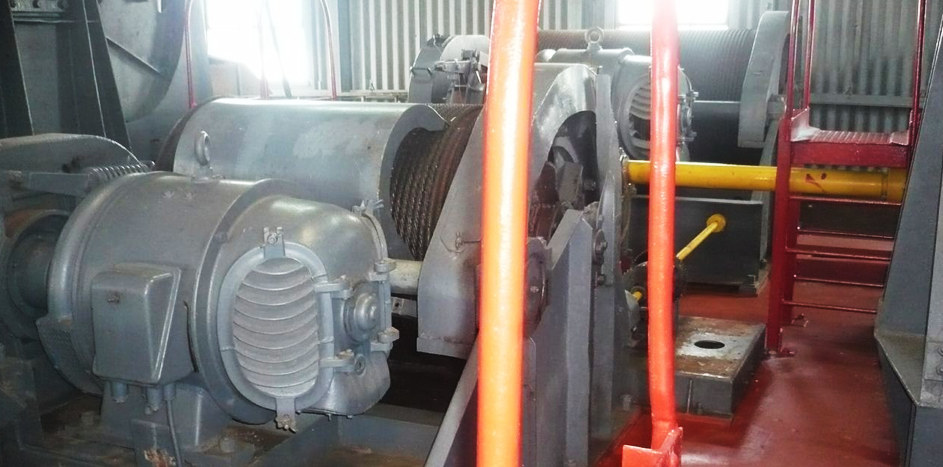

Large Mechanical Gears and Wheels

With caution and suitable containment Sponge Blasting can be conducted on large mechanical components while they are operating. Care must be taken to keep Sponge Media™ abrasives filtered from air intakes and mechanical movement where it could cause damage.

Motors Prepared while Running

A major benefit using Sponge-Jet technology is the ability to blast and prepare operating motors. Not only does a proper coating prevent corrosion, a thin functional coating also helps with heat transfer and preventing motors from overheating and premature failure. The lack of abrasive dust using Sponge Media™ also protects the bearings from grit intrusion.

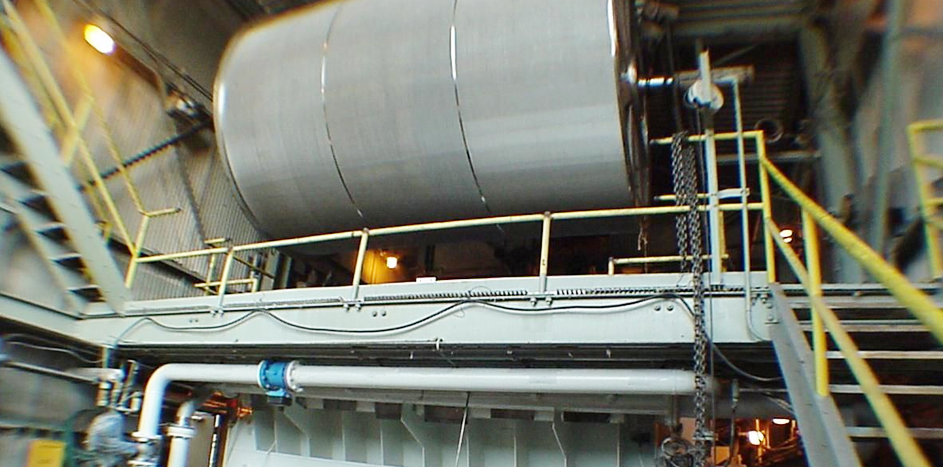

Brown Stock Wash Tank

Pulp and paper mills utilize equipment covered with many intricate moving components. Fugitive emissions from ordinary abrasive blasting can rapidly destroy these components - especially bearings and seals. Sponge-Jet was used to prepare an intermittently used stock tank because all adjacent components would be protected - undamaged and could operate as required.

Sponge-Jet Resource Center

Resources

Sponge-Jet Resource Center

Resources

789 Caster Stand Overhaul at Nucor Steel Mill

Case history showing how Sponge-Jet allowed Nucor Steel Mill first ever opportunity to extend the lo…

Download

Paint Removal in Manufacturing Plant

PDF describes case history of Sponge-Jet low dust coatings removal inside robotics plant containing …

Download

Blog

Recent Blog Posts

Restoration of Tin Ceilings and Walls at Niantic Baptist Church

In the beautiful seaside village of Niantic, Connecticut (USA), sits the historic Niantic Baptist Church. Located on Main Street and just moments from downtown, this Church is positioned at the heart of the small New England community. Unfortunately, in 2022 a fire damaged the church's interior, but fortunately, a Connecticut-based contractor with extensive restoration experience was able to help.

Read More >

Ornamental Tin Ceiling Restoration Project at St. Mark's Church

Located along the main road of Steeleville, Illinois (USA), sits a charming Lutheran Church called St. Mark’s. Surrounded by both homes and businesses in the center of the small town, the Church is a well-known landmark in the community. Prior to a recent renovation, the staff at St Mark's noticed that much of the white paint was peeling off of this decorative ceiling, leaving areas of exposed tin.

Read More >