Find the pages, products, documents, and resources with a full site search.

Advanced Document SearchProtect Military Assets And Readiness

Subjected to the most rigorous environments, military equipment is expected to operate at top performance at all times. Corrosion prevention is a priority to maintain equipment; naval vessels, aircraft, vehicles, heavy equipment and armament. Sponge Media™ blasting can prepare most surfaces, including:

- Advanced materials & armored plates

- Aluminum

- Bronze

- Brass

- Super duplex

- Stainless steel

- Composites

- Fiberglass

- High-strength steel and alloys

Selectively strip coatings, remove contaminants and hazardous materials from substrates without generating the excessive dust environments or ricochet damage normally encountered when rehabilitating assets. Sponge-Jet prepared surfaces optimize coating life and asset readiness.

Features & Benefits

- Decontaminate, entrap and abate hazards

- Simplify job staging

- Protect integrity & reliability of equipment

- Increase asset life and coating performance

- Reliably schedule & budget

- Improve worker health and safety

Protecting Adjacent Coatings During Bilge Space Spot Repairs

Newport News Shipbuilding used Sponge Media™ abrasives during a maintenance overhaul to conduct bilge space repair on the Nimitz class Super Carrier USS Carl Vinson (CVN-70); the choice was made based on the technology’s ability to protect adjacent coatings from abrasive ricochet, which is known to cause pinhole corrosion.

Australian Navy Barge uses Sponge Media™ over Ordinary Abrasives

Sponge-Jet wins out over ordinary abrasives on the exterior overhaul of Australian Navy barges; cost of dust (abrasive cleaning/collection labor, inability to work nearby blasting and inability to reuse abrasives) all cut by Sponge-Jet - savings calculated to $120,000 per barge.

Effective Removal of Abrasive/CARC Coating with Sponge-Jet

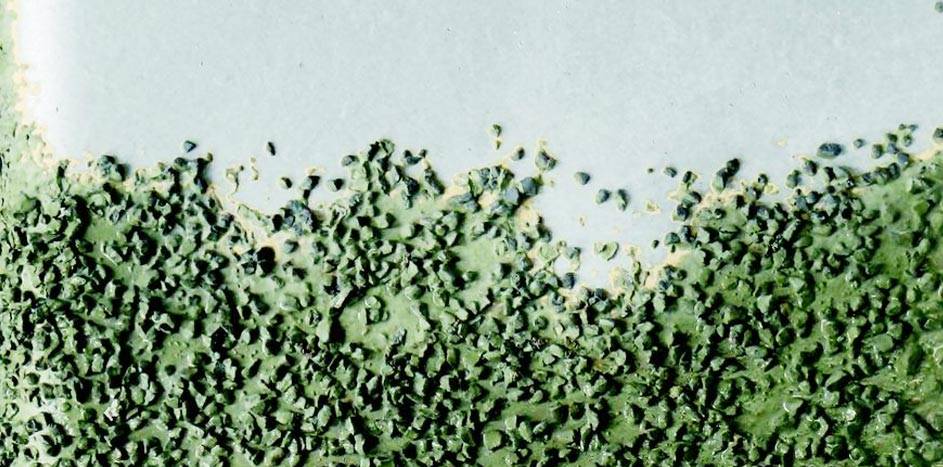

Aggressive grades of Silver Sponge Media™ abrasives make easy work of removing chemical agent resistant coatings like those used on the surface of this Middle East Army vehicle.

Sponge-Jet Removes Toughest Marine Coatings; e.g. top-side non-skid.

Thai navy turns to Sponge-Jet to remove non-skid coating from perimeter deck of aircraft carrier; the process achieved specified Near White Metal Blast Cleaning Sa2.5 (NACE 2 / SSPC SP-10).

US NAVY turns to Sponge-Jet for Protection from Grit Intrusion

Blasting gun turret on US Navy ship; chose Sponge-Jet to limit grit intrusion of the rotating parts (e.g. bearings and seals)

NAVSEA Expects 15-20 year Life-span for Sponge-Jet Blasted Substrates

NAVSEA directive turns to Sponge-Jet to obtain 15-20 year lifespan on new coating systems in the bilge tank of this USN LHD 6 amphibious assault ship; With greatly enhanced visibility and low rebound, blasters are able to strictly adhere to the specified Sa3 (NACE 1 / SSPC SP-5) White Metal Blast Cleaning finish.

Canadian DND Calls for Sponge-Jet to Replace Ordinary Abrasives

Sponge-Jet abrasives are used for restoring pressure hull and outer shell mounts (removing tile adhesive and corrosion); Canadian Department of National Defense and NAVSEA have approved the use of Sponge-Jet as a replacement for ordinary abrasives.

Sponge Blasting Military Vehicles; One-step Coating Removal, Cleaning and Profiling

Military restoration contractor blasts hummer with Sponge-Jet; Silver 80 Sponge media™ abrasive removes coating and imparts 65 micron (2.5mil) profile.

Precision Control to Selectively Strip Coatings

Selective coating removal, carefully exposes chromate primer on aircraft; Sponge-Jet was the perfect solution to selectively strip and expose harmful hexavalent chromium-based primer because it’s controlled abrasion and extreme dust-suppressing properties.

Centro Risorse Sponge-Jet

Risorse

Centro Risorse Sponge-Jet

Risorse

170-CG Feed Unit Manual – ITA

SPONGE-JET 170-CG MANUALE D’USO | 1

Scarica

SPONGE-JET

170-CG Feed Unit

MANUALE D’USO

Sponge-Jet…

Detonazione asciutta con poca formazione di polvere

Detonazione abrasiva asciutta

con un 99,9% di polvere in meno

Controlla la polvere nell’aria v…動画を表示する

Sponge-Jet Introductory Brochure – ITA

Tecnologia di sabbiatura abrasiva

Scarica

a bassa emissione di polvere

Proteggere ciò

che è importante

n L…

Paragone di Tecnologia di Detonazione Abrasiva

Paragone di Tecnologia di Detonazione Abrasiva

Scarica

Abrasivi convenzionali incastrati nella Sponge MediaM…

Blog

Recent Blog Posts

Robotica Saves Disposal and Labor Costs in Mexico

Pipelines are crucial for transporting clean water from treatment plants to cities, businesses, and homes. By maintaining a closed piping system from the source to the faucet, water utilities reduce the risk of water contamination. During the manufacturing of these pipes, proper surface prep must be completed to ensure that they maintain their integrity after coating and installation.

Per saperne di più >

How Sponge-Jet Helped Restore Paris's Grand Palais for the 2024 Olympics

Every four years, billions of people from all around the globe unite to watch the Olympic Games.Hosted in renowned cities worldwide, this year’s Olympic Games will be held in Paris, France. They have only been held in Paris, France twice before - in 1900 and 1924. Now, 100 years later, Paris will once again become the world stage for these iconic games.Per saperne di più >