Find the pages, products, documents, and resources with a full site search.

Advanced Document SearchIs Surface Preparation Below Your Radar?

Compromising coating performance is your decision. Allowing power-tools, water-blasting, poor quality abrasive blasting or perhaps nothing at all, can start an immediate and accelerated cycle of corrosion and repair. Protect your assets and choose performance with a quality coating system prepared by Sponge Blasting; achieve a 30-year coating system with reduced maintenance! Don’t allow “minor” overlooks such as:

- Weld seams

- Girders

- Confined spaces

- Engineering spaces

- Engine rooms

- Erection and construction joints

- Doors, hatches, tie-downs and fit-out items

- Touch-up and repairs

Improve ship availability and reduce cost due to delays, repairs, additional surveys and extended docking. The high angularity of dry, low dust, low ricochet Sponge-Jet Sponge Media™ abrasives, allow you to prepare the critical points of your vessel to the highest quality standard.

Features & Benefits

- Increased Asset Life and Coating Performance

- Reliability of Schedule & Budget

- Improve Community Relations & Compliance

- Efficiently Comply with Changing Regulations

- Simplified Job Staging

- IMO Compliant – No Power Tooling

Blasting Ship Infrastructure Blocks Corrosion; Helps Extend Long Operational Life

The Sponge-Jet blasting of deck beams and parts of transverse frames is a valuable practice because it assures highest quality surface preparation in high-corrosion areas like nuts, bolts, joints, welds, and steel edges

Sponge Blasted Ballast Tanks Pass Ten Years of Fully Functional and Intact Coatings

Sponge-Jet was used to prepare ballast tanks and erection welds by Sumitomo Shipyard on the first double-acting ship in the world; the crude oil tanker, Tempera was recently inspected. Over ten years later it revealed her ballast tanks to have fully functional and intact coatings.

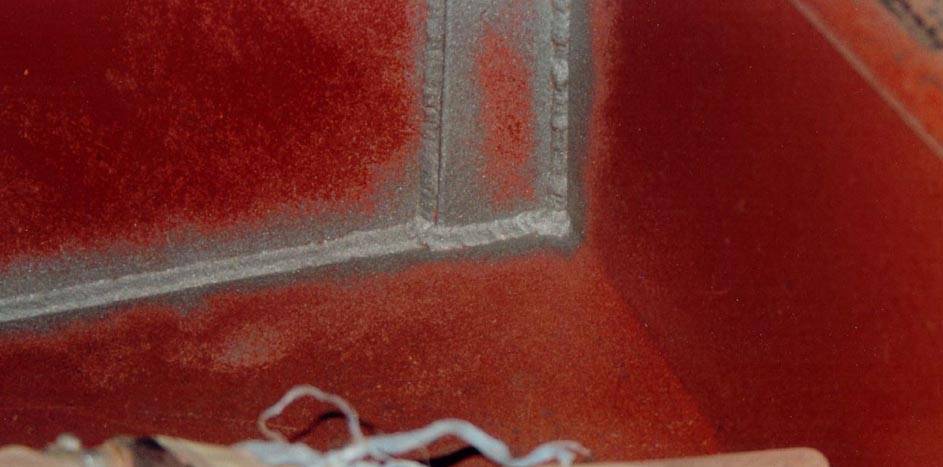

High-quality Sponge-Jet Surface Preparation on Weld Seams and Critical Area Corrosion

Example of ballast tank weld seam that was Sponge-Jet blasted in LeHavre, France to SA3 (NACE 1 / SSPC SP-5), White Metal Blast cleanliness.

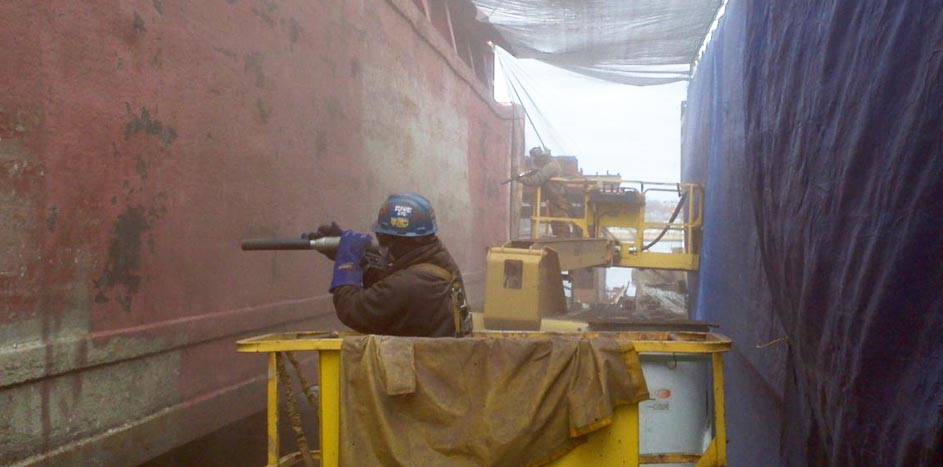

Sponge-Jet Out-Performs Hand-tooling in Speed and Coating Longevity

On this bulk carrier hull, Sponge-Jet was faster than five simultaneous hand-tool operators in preparing weld seams for coatings - and was able to leave an 87-micron (3.5mil) specified profile.

Chilean Navy’s Only Option for Abrasive Blasting in Engine Room of Oscar Viel Toro

Ordinary abrasives were prohibited on a recent pipe coating project aboard the Chilean Navy’s Antarctic Icebreaker, the “Oscar Viel Toro”; the only product specified and used was low dust Silver Sponge Media™ abrasives; the reason was the job’s proximity to the engine (with dust susceptible valves, pumps and rotating fixtures).

Canadian DND Specifies Sponge-Jet as Replacement Abrasive on the Submarines

Sponge-Jet abrasives are used for restoring pressure hull and outer shell mounts (removing tile adhesive and corrosion); Canadian Department of National Defense and NAVSEA have approved the use of Sponge-Jet as a replacement for ordinary abrasives.

Other Trades Effectively Work on Ship Propulsion System While Operator Sponge-Blasts

A Sponge Blaster at SLS Shipyard Co. Ltd. (Korea) cleans and profiles weld seams after construction on the hull of this ship is completed; dust and rebound suppression during this type of blasting allows for other trades to work simultaneously and in close proximity.

Abrasive Blasting this Tank During Inspection; Possible Only with Sponge-Jet

Sponge-Jet abrasive blasting in the tank of a chemical tanker at SLS Shipyard Co. Ltd. (Korea); The ability to inspect and/or schedule work nearby Sponge Blasting is precisely why shipyards are able to cut days from new build and refit projects.

Enhanced Visibility and Safety Realized by this SLS (Korea) shipyard Sponge Blaster

Sponge-Jet abrasive blasting in the ballast tank of a chemical tanker at SLS Shipyard Co. Ltd. (Korea) after block erection is completed; note the enhanced visibility and safety with which the blaster works in while using Sponge Media™ abrasives.

Sponge-Jet Used To Prepare Hull on “Issham Al Baher” - the World's 17th Largest Yacht

Goals were to remove coating, add resin layer and new coating but in a small commercial port versus a large shipyard (saving well over $200,000)… goals achieved and only possible by using low dust Sponge Media™ abrasives which protected neighboring town from potentially harmful fugitive emissions.

Two Sponge Blasters Effectively Spot-blast BMLP barge; Note Low Dust

Two Sponge Blasters conduct hull repair on a BMLP barge at Buchanan Marine; shipyard location is next to residential neighborhood. The town relies on tourism so Buchanan uses Sponge-Jet abrasives to trap dust at the source.

Sponge-Jet used on New-build Workboat Hull for Incredible Visibility and Job Cleanliness

Two Sponge-Jet blasters prepare the hull of a new z-drive tug boat at Washburn and Doughty shipyard; Note the project cleanliness and near perfect visibility which made the specification of a SA3 (NACE 1 / SP-5) White Metal Blast cleanliness level (in a single pass) easily achievable.

Blasting New-build Hull at Waterside Without Dust Issues no Problem Using Sponge-Jet

Low dust, Sponge-Jet blasting the hull of a new z-drive tug boat at Washburn and Doughty shipyard; Note the ocean just meters/feet from blasting operations, which would normally be prohibited when using ordinary abrasives – but not with Sponge-Jet according to operators.

Entire Structure of New York Water Taxis Are Sponge Blasted

Gladding-Hearn Shipbuilding and Sponge-Jet help thousands get to work each day; Sponge-Jet is used to prepare aluminum substrates of every New York Water Taxi for coating; Reasons... Gladding-Hearn has desire to recycle and reduce abrasive disposal volume/weight and they can blast in-doors with multiple ships in process during blasting and without interruption.

Sponge-Jets resurscentrum

Resources

Sponge-Jets resurscentrum

Resources

Extending Barge Life Case History on Barge Restoration

PDF technical paper describes benefits of bringing barge blasting operations in house and using Spon…

Download

Marine Application Index

Brochure that shows marine industry use of Sponge-Jet low-dust abrasive blasting.

Download

Marine Overview Video

Sponge-Jet’s low dust abrasive blasting technology is widely used in the marine industry by mi…

View Video

Prep for Life Marine Maintenance Tech

PDF magazine article describes modern marine coating’s higher anchor profile requirements and the …

Download

Blogg

Recent Blog Posts

How Sponge-Jet Helped Restore Paris's Grand Palais for the 2024 Olympics

Every four years, billions of people from all around the globe unite to watch the Olympic Games.Hosted in renowned cities worldwide, this year’s Olympic Games will be held in Paris, France. They have only been held in Paris, France twice before - in 1900 and 1924. Now, 100 years later, Paris will once again become the world stage for these iconic games.Läs mer >

How do Contractors Use Sponge-Jet for Abatement Work?

Jobs that are characterized as "abatement projects" typically involve the removal of hazardous materials from the surface. These types of projects are often found in places like industrial shipyards, factories, tanks, water treatment plants, mill buildings, and generally any building or structure built before 1980.

Läs mer >