Don’t Let Abrasives be the Root Cause of a Shutdown

Avoid disruptions to rehabilitation / construction projects that are associated with surface preparation and the dusty conditions associated with ordinary blasting. Protect sensitive equipment normally effected by blasting operations. For example:

- Motors

- Mechanical seals

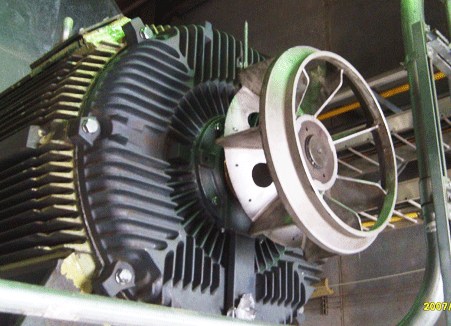

- Compressors

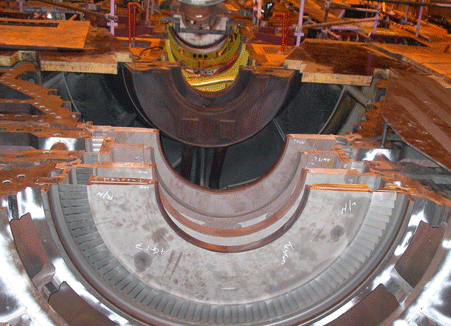

- Rotating equipment and bearings

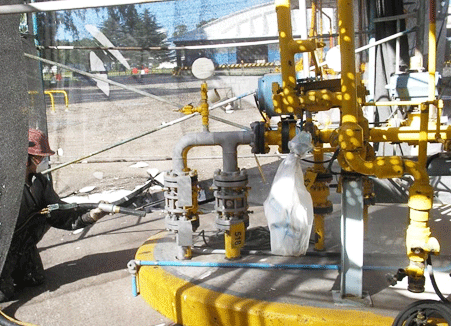

- Hydraulic and pneumatic cylinders

- Exchangers

Sponge blasting reduces dust and abrasive ricochet, which allow project managers to consolidate and schedule other trades to work in close proximity; tasks normally delayed can now be accomplished simultaneously by Sponge Blasting – to shorten project schedules and reduce the high costs of downtime.

Testimonials

"Great Equipment and World Class Service from you folks has been instrumental in our ability to meet our clients’ needs here at SIEMENS Westinghouse in Charlotte NC.” - Dave Jordan, Materials Engineering Technician, Westinghouse Electrical Company

Related Resources

Being Green Good Article

PDF article describes Sponge-Jet’s greener approach to preserving structural assets and boosting p…

Download

Blastoff Coatings Pro

PDF magazine article discusses Sponge-Jet abrasive blasting on two pilot boats used in the New York …

Download

EcoPetrol Safety Bulletin

PDF case history document created by Ecopetrol, Colombia’s principal petroleum company, describing…

Download

Sponge-Based Technology Can Cut Cleaning Downtime

PDF article describes abrasive-blast airborne dust problem encountered at manufacturing facilities.

Download

Recent Blog Posts

How Sponge-Jet Helped Restore Paris's Grand Palais for the 2024 Olympics

Every four years, billions of people from all around the globe unite to watch the Olympic Games.Hosted in renowned cities worldwide, this year’s Olympic Games will be held in Paris, France. They have only been held in Paris, France twice before - in 1900 and 1924. Now, 100 years later, Paris will once again become the world stage for these iconic games.Read More >

How do Contractors Use Sponge-Jet for Abatement Work?

Jobs that are characterized as "abatement projects" typically involve the removal of hazardous materials from the surface. These types of projects are often found in places like industrial shipyards, factories, tanks, water treatment plants, mill buildings, and generally any building or structure built before 1980.

Read More >