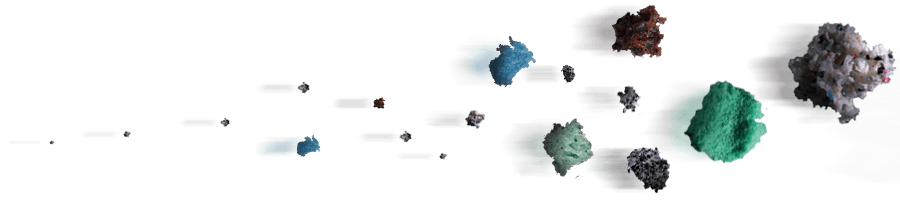

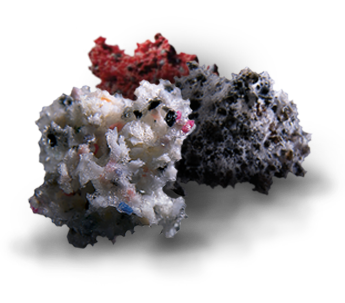

Sponge-Jet has engineered a line of composite abrasives, incorporating the best abrasives or micro-abrasive particles, within high-performance synthetic sponge. The diverse range of recyclable composites provide superior results for aggressive profiling and abrading or delicate cleaning on highly sensitive substrates. The synthetic sponge captures up to 95% of the contaminants, reducing fugitive emissions through its MicroContainment™ feature.

Find the pages, products, documents, and resources with a full site search.

Advanced Document Search-

Sponge Media & Abrasives

MoreSponge Media & Abrasives -

Application Tools

Unlike most equipment manufacturers whose business model relies on profits from spare parts and breakdowns – the Sponge-Jet business model is measured by the operational performance of equipment. These units are built to deliver a consistent flow of media into an air stream by use of a pneumatically controlled auger system. In order to achieve maximum production and reliable performance, each unit has an actuator-driven agitator (or “tree”) to keep the media in a fluid-like flow-state.

MoreApplication Tools -

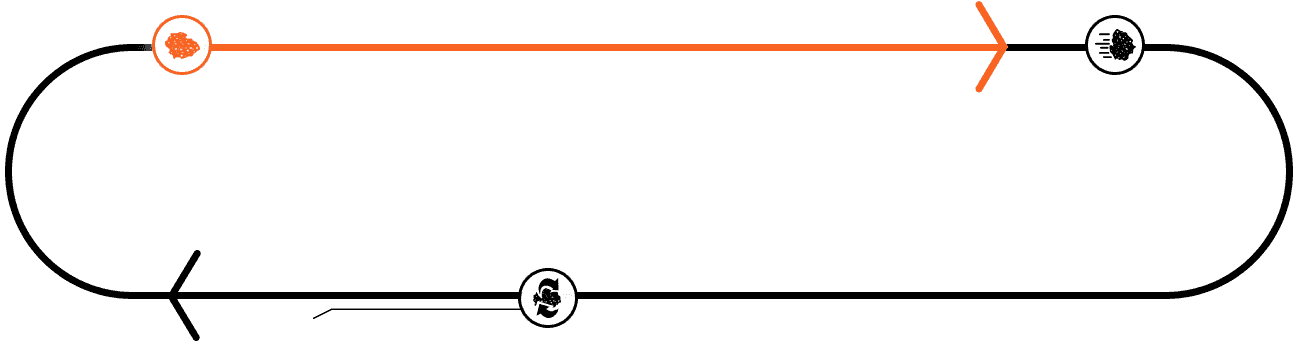

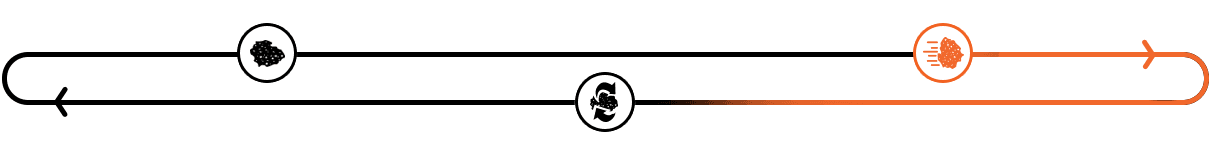

Recycling

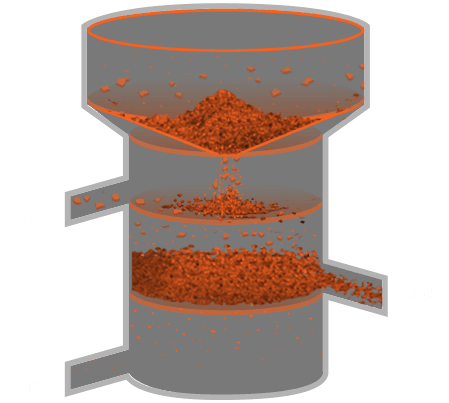

Recyclers use rapid vibrations to shake and tumble reusable Sponge Media in a spiral path over a series of screens; each size-selected to achieve the desired result. The first coarse screen separates and ejects unwanted, over-sized contaminants (into a waste bucket) that may have been recovered with the blasted Sponge Media. The second screen separates (into another waste bucket):

- Fine dust

- Hazardous contaminants (e.g. lead, PCB, asbestos, radioactive particles)

- Stripped/broken-down coatings

- Fractured abrasives

Recycled media (typically >95% ) is funneled into a third bucket and ready for reuse – and when merged with a small amount of new media, it creates a consistent “working mix”. The screen opening size of the lower screen and ratio of new media can be adjusted to optimize the balance between acceptable dust levels and maximum media life. Recycle, Reuse, Reduce!

MoreRecycling