Find the pages, products, documents, and resources with a full site search.

Advanced Document SearchIncreased Production, Reduced Costs

Lean manufacturers can cost-effectively increase production by reducing rework and eliminating unnecessary time-consuming steps. Sponge-Jet technology allows companies around the world to reduce the time associated with surface preparation by integrating it directly into the production site. Applications include:

- High Tech & Light Manufacturing

- Heavy Industry

- Molded Parts (e.g. slush, pressure and injected)

- Surface Finishing

- Composite Manufacturing

- Agricultural & Heavy Equipment

- Wind Turbines

- Food and Beverage

- Pipe Manufacturers

- Steel Fabricators

Less time is wasted on transportation to either an in-house blasting facility or outside third party. Overall quality is increased due to reduced handling, transportation and contamination from exposure to the elements.

Features & Benefits

- Reduced rejection & rework (Six Sigma Quality)

- Reliability of schedule & budget

- Improve community relations and compliance

- Reduce manufacturing steps improving integration

- Increased production & profits

- Equipment reliability and asset life extension

Sponge-Jet Replaces Manual Hand-cleaning of Tire Molds

Gulf-coast tire manufacturer chose Sponge-Jet to remove accumulated release agent from inside and outside mold surfaces; blasting compared to more time-consuming and inconsistent hand-cleaning saved significant time per mold.

Sponge-Jet Saves Manufacturer Hours in Labor Cleaning Slush Molds

Automobile slush mold cleaning with Sponge-Jet for one manufacturer is a proven time and money saver; in some cases it cut cleaning up to eight hours per mold, without removing the leather-like shine in the end product.

Rejected Automobile Bumpers Are No Longer Discarded Because of Sponge-Jet

Automobile bumper manufacturer now recycles rejected bumpers (from coating imperfections) because Sponge-Jet provides highly controllable micro-abrasion and the ability to selectively remove erroneously cured top-coat while leaving the primer intact.

Agricultural Equipment Manufacturer Builds Sponge-Jet into Part Restoration Process

Largest industrial and agricultural equipment manufacturing facility in south America continues to use Sponge-Jet blasting in their production process to prepare repairs of steel parts; for example this front loader bucket.

Sponge-Jet Builds Special-access Blast Room Solution in Refinery

Mexican oil refinery builds special-access Sponge Blasting KwietKave™ solution to blast and repair process parts; bringing blasting and painting operations like this one in-house saves time, money and has been found to improve quality.

Industrial Lift Manufacturer Incorporates Sponge-Jet into Refurbishment Operations

Manufacturer of industrial lift equipment uses Sponge-Jet in a blast room in their manufacturing facility; product replacement and refurbishment operations are greatly simplified solutions when using low dust, low rebound Sponge Media™ abrasives.

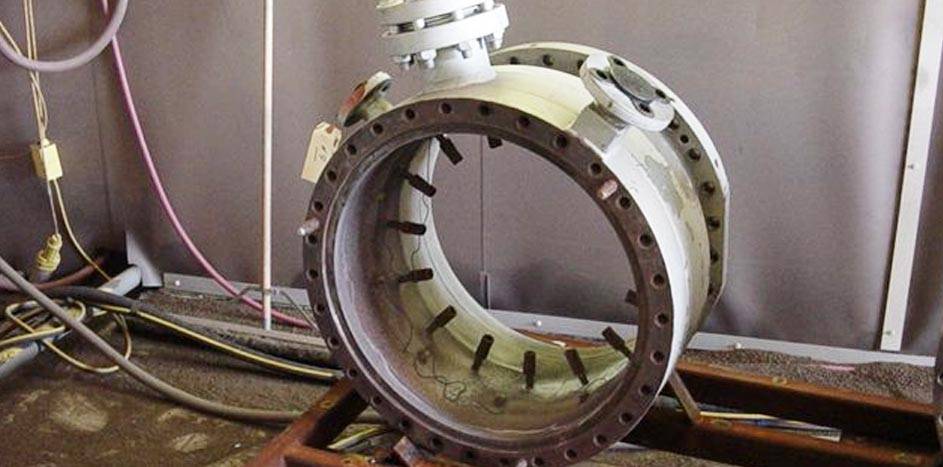

Pump Manufacturer uses Sponge-Jet for Their On-site Coating Warranty Repairs

Coating warranty for largest manufacturer of centrifugal slurry pumps; Sponge-Jet saves thousands in shipping and logistics by allowing Sponge Blasting near the pump seals and bearings at customer installation site.

Sponge-Jetin resurssikeskus

Resources

Blogi

Recent Blog Posts

How Sponge-Jet Helped Restore Paris's Grand Palais for the 2024 Olympics

Every four years, billions of people from all around the globe unite to watch the Olympic Games.Hosted in renowned cities worldwide, this year’s Olympic Games will be held in Paris, France. They have only been held in Paris, France twice before - in 1900 and 1924. Now, 100 years later, Paris will once again become the world stage for these iconic games.Lue lisää >

How do Contractors Use Sponge-Jet for Abatement Work?

Jobs that are characterized as "abatement projects" typically involve the removal of hazardous materials from the surface. These types of projects are often found in places like industrial shipyards, factories, tanks, water treatment plants, mill buildings, and generally any building or structure built before 1980.

Lue lisää >