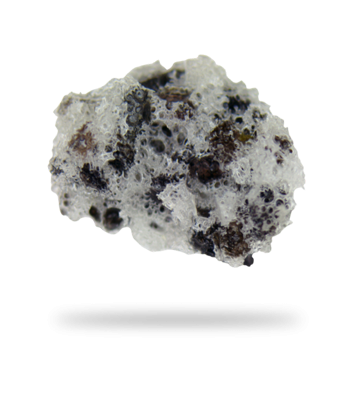

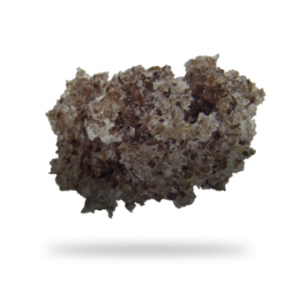

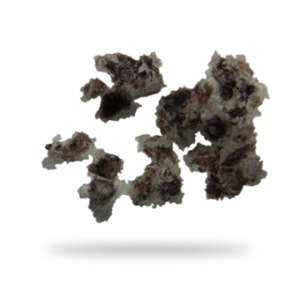

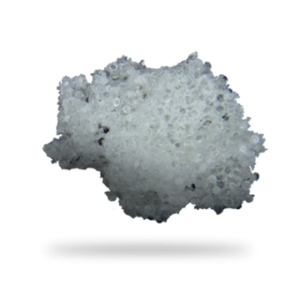

SuperMedia™1 is designed to aggressively remove coatings or contaminants and will impart a high profile on both steel and concrete. The extreme surface roughness this product provides, while too great for most coatings, is well-suited for prep or removal of polyurea and rubberized coatings – as well as for removing hazardous contaminants prior to decommissioning and or disposal. The product is effective at removing 1/4in (6 mm) of concrete at a rate of 120ft² (11m²) per hour – and leaving an ICRI CSP-7 profile without fracturing stone. Abrasive blasting with SuperMedia is an effective preparation for concrete prior to coating and strengthening (with carbon fiber or other composites) – including the application of blast mitigation coatings.

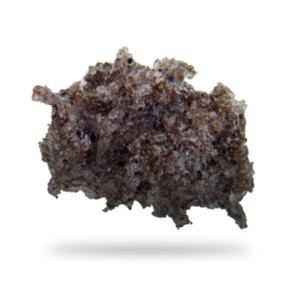

Super Media™1

Specifications

- Product Name: Super Media™1

- Part #: SJM-SUPERMEDIA-1

- Weight: 18.1 kg (40 lb)

- Abrasive / Cleaning Agent: Metal & Ceramic Blend

- CARB Certified: Yes

- Aggressivity Rating: Highly Aggressive

- Achievable Range*: >200 μ (>8 mils)

Features

Safer for workers

- Less worker exposure and fatigue

- Less eye and other injuries

- Contains no Crystalline Silica

Better for the Environment

- Clean, Dry, Low Dust reusable abrasive

- Extremely low dust generation compared to ordinary abrasives

- High Reuse (recycles)

- Lower fugitive emissions

Improved Operational Efficiency

- Enhanced visibility and first-pass quality

- Fewer defects and rework, keeping projects on schedule

- High-quality surface preparation in sensitive or confined areas

- The ability for other trades to work nearby

- A solution for preparing surfaces near finished coatings, instruments and equipment

- Contains no thermal Plastics ( Ideal for Pulp and Paper Mills)

Lower Direct and Indirect Costs

- Low inbound and outbound freight

- Less pollution, waste generation, fines and reporting

- Improved community relations

- Less liability, litigation and compliance reporting

- Less downtime

- Improved asset availability

- Coatings perform longer, saving on future maintenance and acquisition costs

- Easier staging, containment, ventilation and clean up

- Less waste, disposal and material handling

- Greater production and efficiency

- Increased profits and production