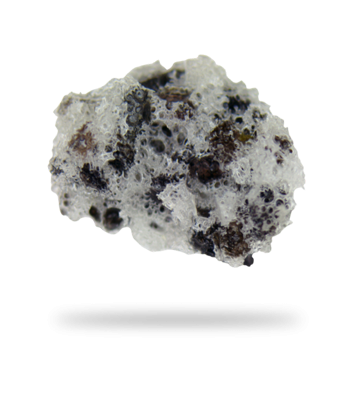

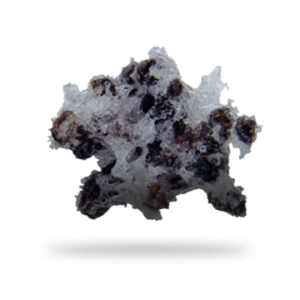

SuperMedia™1 is designed to aggressively remove coatings or contaminants and will impart a high profile on both steel and concrete. The extreme surface roughness this product provides, while too great for most coatings, is well-suited for prep or removal of polyurea and rubberized coatings – as well as for removing hazardous contaminants prior to decommissioning and or disposal. The product is effective at removing 1/4in (6 mm) of concrete at a rate of 120ft² (11m²) per hour – and leaving an ICRI CSP-7 profile without fracturing stone. Abrasive blasting with SuperMedia is an effective preparation for concrete prior to coating and strengthening (with carbon fiber or other composites) – including the application of blast mitigation coatings.

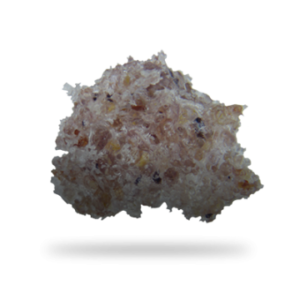

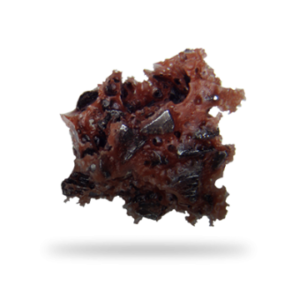

Sponge-Jet has engineered a line of composite abrasives, incorporating the best abrasives or micro-abrasive particles within high-performance synthetic sponge. The diverse range of recyclable composites provide superior results for aggressive profiling and abrading or delicate cleaning on highly sensitive substrates. The synthetic sponge captures up to 95% of the contaminants, reducing fugitive emissions through its MicroContainment™ feature.

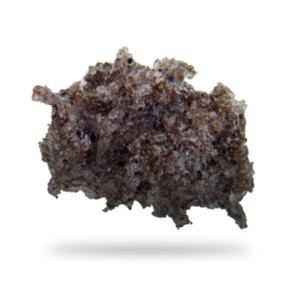

Super Media™1

Specifications

- Product Name: Super Media™1

- Part #: SJM-SUPERMEDIA-1

- Weight: 18.1 kg (40 lb)

- Abrasive / Cleaning Agent: Metal & Ceramic Blend

- CARB Certified: Yes

- Aggressivity Rating: Highly Aggressive

- Achievable Range*: >200 μ (>8 mils)

- Specialty Surface Preparation: Abatement (Lead, PCB, Asbestos), Nuclear Remediation, Radiological Decontamination

- Stripping: Concrete

- Industrial Coatings Removal: Elastomeric Coatings

- Profile Carbon Steel: +200 μ (+8 mils)

Features

Safer for workers

- Less worker exposure and fatigue

- Less eye and other injuries

- Contains no Crystalline Silica

Better for the Environment

- Clean, Dry, Low Dust reusable abrasive

- Extremely low dust generation compared to ordinary abrasives

- High Reuse (recycles)

- Lower fugitive emissions

Improved Operational Efficiency

- Enhanced visibility and first-pass quality

- Fewer defects and rework, keeping projects on schedule

- High-quality surface preparation in sensitive or confined areas

- The ability for other trades to work nearby

- A solution for preparing surfaces near finished coatings, instruments and equipment

- Contains no thermal Plastics ( Ideal for Pulp and Paper Mills)

Lower Direct and Indirect Costs

- Low inbound and outbound freight

- Less pollution, waste generation, fines and reporting

- Improved community relations

- Less liability, litigation and compliance reporting

- Less downtime

- Improved asset availability

- Coatings perform longer, saving on future maintenance and acquisition costs

- Easier staging, containment, ventilation and clean up

- Less waste, disposal and material handling

- Greater production and efficiency

- Increased profits and production